1. Natural rubber roller: excellent flexibility and mechanical strength, good alkali resistance, used for textile, paper making, leather, packaging equipment such as medium voltage type rubber roller and metallurgy, mining industry such as traction type rubber roller.

2. Nitrile rubber roller: excellent oil resistance, and abrasion resistance, aging resistance, heat resistance is better also, used for printing, printing and dyeing, chemical fiber, paper, packaging, plastics processing equipment, and other contact with the occasion of oil and fat hydrocarbon solvent.

3. Neoprene roller: excellent abrasion resistance, high refractory, aging resistance, good heat resistance, oil resistance and acid-proof alkaline, used in PCB etching machine, plastic, leather, printing, food, printing, coating machine and other equipment.

4. Butyl rubber roller, high resistance to chemical solvent, good heat resistance (170 ℃), excellent acid-proof alkaline, suitable for color printing machinery, leather machinery, coating equipment, etc.

5. 3-20 roll: excellent resistance to ozone aging, weathering resistance, wide temperature, can be long-term work under - 65 ℃, 140 ℃, insulation performance is good, for plastic printing machinery, leather machinery, general areas.

6. Polyurethane rubber roller, with high mechanical strength and wear resistance, aging resistance and oil resistance is also quite good, often used in papermaking, chemical fiber, wood processing, plastics processing machinery.

7. Silicone rubber roller: use it has high temperature resistance, ozone resistance, chemical inertness and no adhesive for plastic, used for processing hot sticky products, such as polyethylene calendering, embossing, printing, dyeing and Shanghai juji adhesives, plastic composite film and fabric, corona processing machinery, there are also used as sugar production and packaging on the interpretation of the basic material roll and non-woven fabric manufacturing, etc.

: 8. Fluorine rubber roller with high heat resistant, oil resistant, acid and alkali resistance and other properties, air permeability and electric insulation resistance, ageing resistance, flame resistance, abrasion resistance and other performance is very good also, used for special coating equipment.

According to different rubber roller, we summarize the

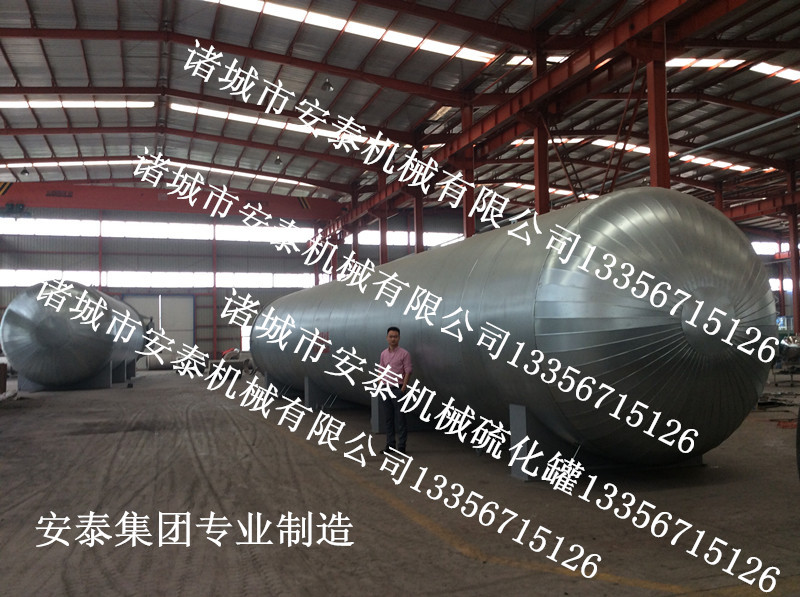

All kinds of rubber roller, butadiene-acrylonitrile rubber roller vulcanizing tank temperature requirements in 150 degrees, vulcanization pressure at about 4 to 5 kg for electric steam curing pot, steam curing, the if there is a boiler to choose according to the customer.

For silica gel roller, curing temperature and pressure is higher, suitable for dry vulcanizing tank, the use of high temperature fan to cycle on the surface of the pot hot air, to ensure temperature uniformity, according to some more demanding customers, in order to keep the surface of the product from oxidation, using vacuum first, then when pressurized with inert gas pressure, the more perfect product